ROKI Filter

What is Micron Filtration(Microfiltration)?

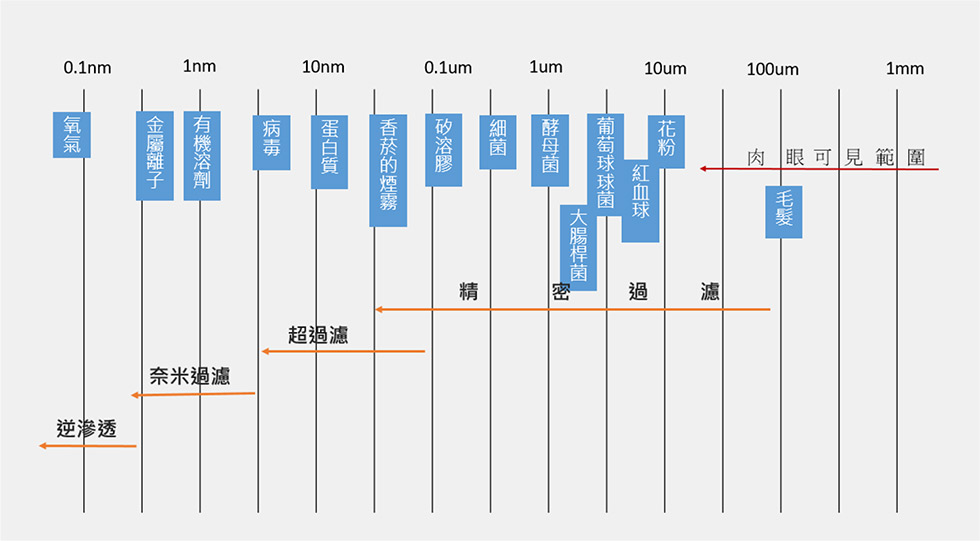

Classify the filtration field according to the size of the particles that need to be screened, and the filtration level can be divided into micron filtration (Microfiltration, MF)、Ultrafiltration (Ultrafiltration, UF)、Nanofiltration (Nanofiltration, NF)、Reverse osmosis (Reverse osmosis, RO) etc.。

Purchasing filter elements and conforming to equipment installation, you should pay attention to those specifications and sizes?

The composition of the filter core can be roughly divided into :

Filter housing、Inner cylinder (center column)、 filter material、support material、 end cap (filter joint)、gasket or Oring、 length and inner and outer diameters, etc.

welcome to inquire,We will provide a complete consulting service.

Filter housing、Inner cylinder (center column)、 filter material、support material、 end cap (filter joint)、gasket or Oring、 length and inner and outer diameters, etc.

welcome to inquire,We will provide a complete consulting service.

There are many kinds of filter end caps (joints), how to choose?

The filter element is installed in the filter equipment, under the pressure of the fluid, it needs to be fixed in a good way to ensure no leakage, so as to avoid the failure of the filter.

End caps are the best choice to ensure fixation and tightness. There are many kinds of end caps in industrial use. The choice should conform to the style that can be installed by the original equipment, and consider that the Oring or gasket material has sufficient chemical resistance.

End caps are the best choice to ensure fixation and tightness. There are many kinds of end caps in industrial use. The choice should conform to the style that can be installed by the original equipment, and consider that the Oring or gasket material has sufficient chemical resistance.

What do nouns such as upstream and downstream nouns mentioned in general filtering mean?

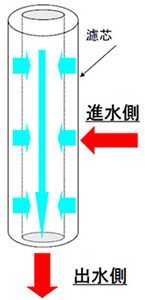

The direction in which the liquid fluid moves through the filter core during filtration is shown in the figure below. The fluid flows from the outside to the inside, and the fiber diameter of the filter material also has a formula from coarse to fine. Therefore, the outer diameter is usually the upstream end, and the inner diameter is usually the downstream end.

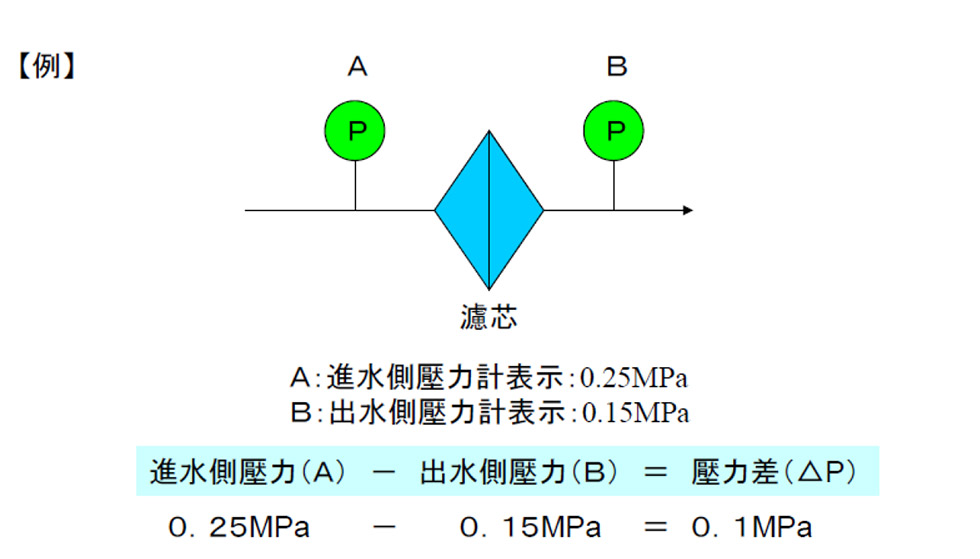

What does the pressure difference mentioned in filtration mean?

An increase in the pressure difference of the filter element and a decrease in the flow rate represent the blockage of the filter element. In the field of the filter element, the pressure difference between the inlet side and the outlet side is called differential pressure.

Inlet side pressure(A)-Outlet side pressure(B)=differential pressure (△P)

Inlet side pressure(A)-Outlet side pressure(B)=differential pressure (△P)

What is absolute filtering? What is relative filtering?

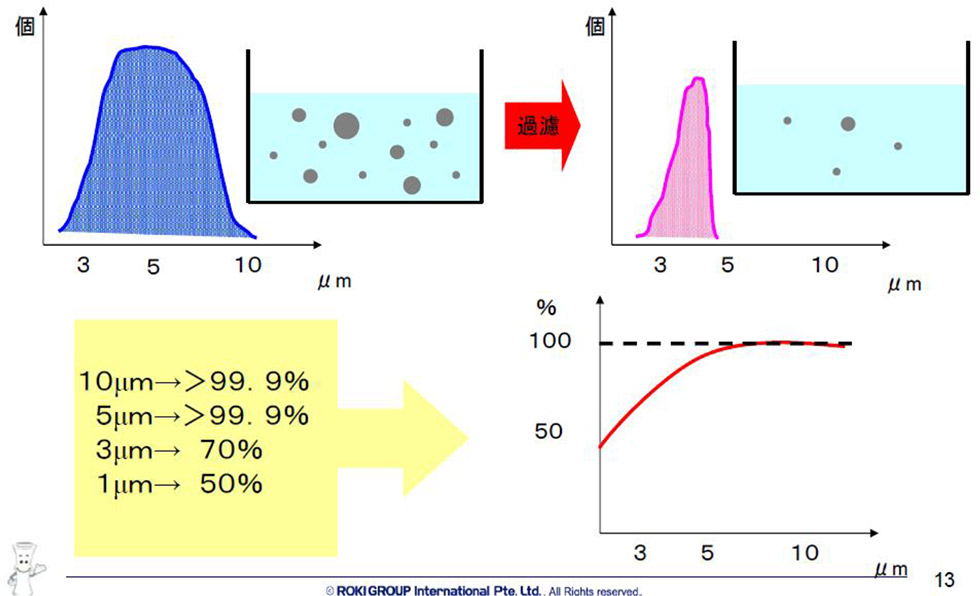

The filtration efficiency of the filter element refers to the percentage of the number of particles before and after the filter after the fluid passes through the filter element. It can be roughly divided into absolute filtration and relative filtration.

For example, the yellow color block analyzes the performance after filtration. This filter

Particles above 5um are absolutely filtered, and 99.9% of the particles larger than 5um are retained by the filter core.

Particles above 3um are relatively filtered. Using the filter core, about 70% of the particles above 3um are still retained.

ROKI for each sales model, the filter efficiency table measured by the laboratory under the specified conditions is provided to the user, which can be used as a reference for the initial selection of filter elements.

And according to different testing methods, there are not small differences among brands, customers need to choose professional and stable quality brands.

Particles above 5um are absolutely filtered, and 99.9% of the particles larger than 5um are retained by the filter core.

Particles above 3um are relatively filtered. Using the filter core, about 70% of the particles above 3um are still retained.

ROKI for each sales model, the filter efficiency table measured by the laboratory under the specified conditions is provided to the user, which can be used as a reference for the initial selection of filter elements.

And according to different testing methods, there are not small differences among brands, customers need to choose professional and stable quality brands.

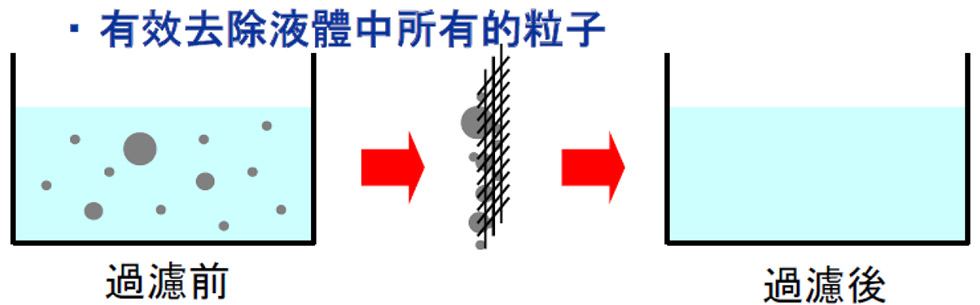

What is Clarification Filtration?

Clarification filtration is to effectively remove all particles in the liquid, usually using a filter element with high precision and absolute filtration efficiency.

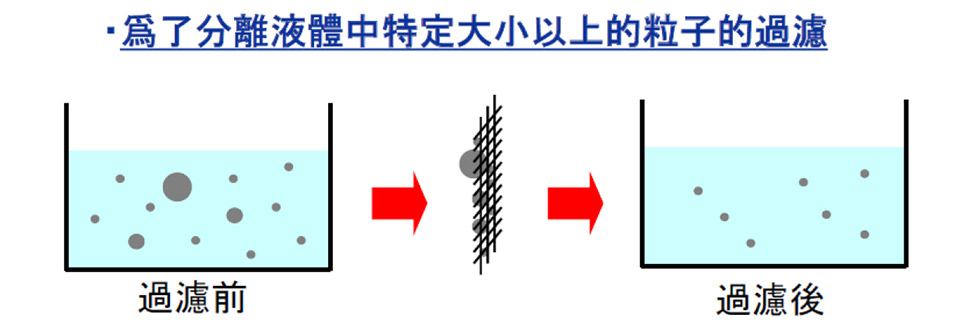

ROKI What are we talking about hierarchical filtering?

Separates particles above a specific size in a liquid, retains necessary fine particles, and removes only unnecessary coarse particles.

ROKI Over the years, we have worked hard to pursue grading technology to solve many unbreakable problems in material development.

ROKI Over the years, we have worked hard to pursue grading technology to solve many unbreakable problems in material development.

What are the main filter materials for filtration?

The choice of material needs to consider whether it can resist solvent, whether its physical characteristics reach the working range of filter diameter and the highest temperature it can withstand. We have a variety of filter materials such as PP, NYLON, TEFLON, PES, GLASS FIBER, etc., welcome to inquire.

When to Replace Filters?

The pressure difference is an important index to judge the life of the filter element. Generally, the set working pressure is about 0.5-3 kg. If the pressure rises to exceed the set standard value (design according to different conditions), the filter element needs to be replaced.

Periodic exchange (meaning a fixed time period) and batch exchange (meaning a fixed amount of material usage) are good practices for maintaining filtration quality.

Periodic exchange (meaning a fixed time period) and batch exchange (meaning a fixed amount of material usage) are good practices for maintaining filtration quality.